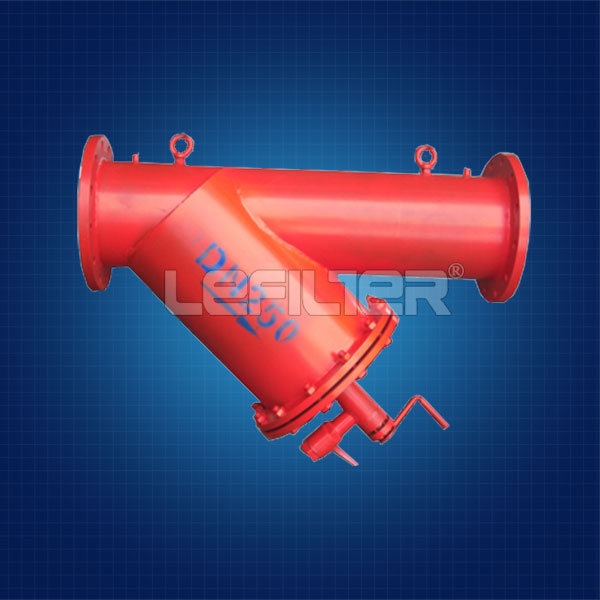

Automatic cleaning filter housing

Introduction:Automatic cleaning filter housing Thewaterflowsthroughthescreenandtheparticlesareretainedontheinsideofthescreenofthefilterelement.Thefilteredwaterthenflowsoutthroughtheoutlet. Whentheparticlesaccumulatedtoacertainnumberandthepressurediffere

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Automatic cleaning filter housing

The water flows through the screen and the particles are retained on the inside of the screen of the filter element. The filtered water then flows out through the outlet.

When the particles accumulated to a certain number and the pressure differential increases to the pre-determined level, the flushing cycle starts.

It include two steps: First, the automatic drain valve opens on the drainage outlet. Then, electronic motor drives the cleaning brushes which are inside the screen, the solids are expelled through the drain valve.

Filters continue to supply filtered water even during the flushing cycle.The whole working system is controlled by a smart box which has several control modes: pressure differential, time, manual and PLC.

DLD series automatic have much advantages:wide filtration range,short flushing time,low water consumption,low pressure loss etc.

Technical parameters

| Single filter flow(max) | 4000m3/h |

| Filtration range | 20-4000 micron |

| Working pressure | 0.18-1.6Mpa |

| Adjustable flushing time | 10-200 seconds |

| Power supply | 380 v / 50 Hz , AC24V |

| Control modes | Pressure difference/time/manual/PLC |

| Shell material | Carbon steel |

| Screen material | 304 stainless steel/316L |

Product selecting

When you are choosing automatic screen filters, please consider the following parameters:

1. Flow capacity( Pipe diameter)

2. Filtration range

3. Shell materai

4. Pipeline pressure

5. Chemical properties of the filter medium

6. Suspended solids(SS) concentration of filter medium

Please fill in your procurement needs and contact information