- HOME

- PRODUCT

- PRODUCT

- Oil Filtration Service

- Water Filtration Solutions

- Seawater Desalination System

- Air Filtration Technology

-

Oil Filtration Service

Oil Purifier Machine

Filter Assembly

Hydraulic Filter Element

Hydac

Pall

more>

-

Water Filtration Solutions

High flow cartridges

Self-cleaning filter

Cartridge filter housing

Bag filter housing

Water filter cartridges

more>

-

Seawater Desalination System

RO Membrane

Reverse osmosis equipment

Ultrafiltration equipment

Demineralized water equipment

more>

-

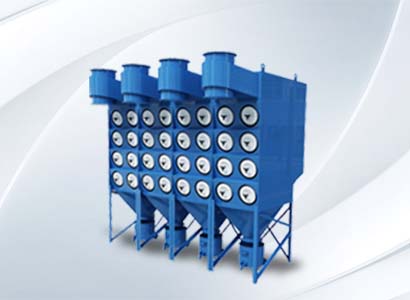

Air Filtration Technology

LEFILTER

Dust Filter Cartridge

Pleated Bag Cartridge

Air Compressor Filter

HEPA Filter

more>

- EPC

- ABOUT

- SUPPORT

- CONTACT