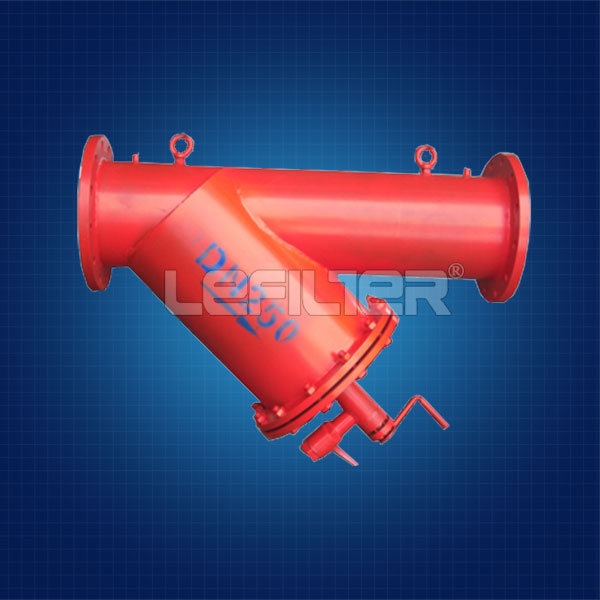

304/316L Automatic Back Flushing Filter For Cooling Blast Fu

Introduction:304 / 316L / CS Automatic Back Flushing Filter For Cooling Blast Furnaces Self Cleaning To customer detail 01. What is the capacity (m3/hour)you required for this equipment? 02. What is the material for this bag filter? Stainless steel (SS3

We're here to help:

Easy ways to get the answers you need.

Product parameter:

304 / 316L / CS Automatic Back Flushing Filter For Cooling Blast Furnaces Self Cleaning

To customer detail

01. What is the capacity (m3/hour)you required for this equipment?

02. What is the material for this bag filter?

Stainless steel (SS304/SS316)?

03. What is the working pressure for it?

04. What is the filtration degree?

10 micron or 200 micron?

| Applicable Liquid | Water and liquid of low viscosity(<40cps), contaminant<300ppm |

| Lowest Working DP | Differential pressure between the outlet and discharging outlet >0.15MPa |

| Filtration Rating | 50-2000μm |

| Design Pressure Class | 0.6MPa/1.0MPa/1.6MPa/2.0MPa |

| Design Temperature | 0-95°C |

| Flowrate Range | 17—8000m³/h |

| Filter Area | 4970cm²-89530cm² |

| Self-cleaning DP | 0.05MPa—0.07MPa |

| Control System | parallel control of differential pressure and time |

| DP Instrument | Differential pressure transmitter, differential pressure switch |

| Gear Motor | 120W, three phase, 380V, protection class IP55, CCWU |

| Inlet and outlet size | 2"—24" |

| Connection Standard | flange,HG20592-2009(Standard Design), HG20615-2009(ANSI B16.5 compatible) |

| Filter Element | V-SLOT series slotted screen, material 316L/SuperDuplex/Ti2 |

| Wet Part Material | 304/316L/CS, special material available (such as 904L,duplex S.S.) |

| Inner Lining | Epoxy, PA11 for CS Housing or special anti-corrosion requirement |

| Housing Sealing Material | NBR(Standard/VITON(FKM) |

| Discharging Valve | Pneumatic stainless steel valve or butterfly valve, protection class IP65 |

Automatic Back-flushing Filter is a new generation self-cleaning filtration system independently designed by, it is integrated with a number of slotted filter elements. When the filter elements are clogged, a specially designed back-flushing arm will clean the elements one by one. As the high-end self-cleaning filter, it is especially designed for customers who take good quality and high eliability into consideration firstly .The filter consists of world-class top quality crucial parts, such as filter element, gear motor, control system, etc..

Automatic Back-flushing Filter can remove the solid particles from various water resource and low viscosity liquid (e.g. machining coolant ). It makes the fluid meet cleanness requirement and protects downstream key equipments from clogging, abasing and fouling. It increases the key equipment running efficiency and service life. XF Filter automatically works continuously on-line and reduces the downtime cost, maintenance cost and labor cost. Automatic Back-flushing Filter is the advanced solution for the self-cleaning filtration of water and low viscous liquids.

Automatic Back-flushing Filter can remove the solid particles from various water resource and low viscosity liquid (e.g. machining coolant ). It makes the fluid meet cleanness requirement and protects downstream key equipments from clogging, abasing and fouling. It increases the key equipment running efficiency and service life. XF Filter automatically works continuously on-line and reduces the downtime cost, maintenance cost and labor cost. Automatic Back-flushing Filter is the advanced solution for the self-cleaning filtration of water and low viscous liquids.

Applications:

Applicable industries: Water treatment, steel, pulp and paper, mining, petro-chemical, machining, municipal, irrigation etc.

Typical applicable liquids: Groundwater, seawater, lake, reservoir water, pond water, cooling water circulation, frozen water, high and low voltage gush to drench water, squirt water, heat water, seal water, bearing cooling water, oil wells note water, process of circulating water, machining coolant, cleaning agents, cleaning water, etc.

Contact information:

Name:Steven

Skype/Email:sales07@lefilter.com

Phone/WhatsApp:0086-18568229226

Please fill in your procurement needs and contact information