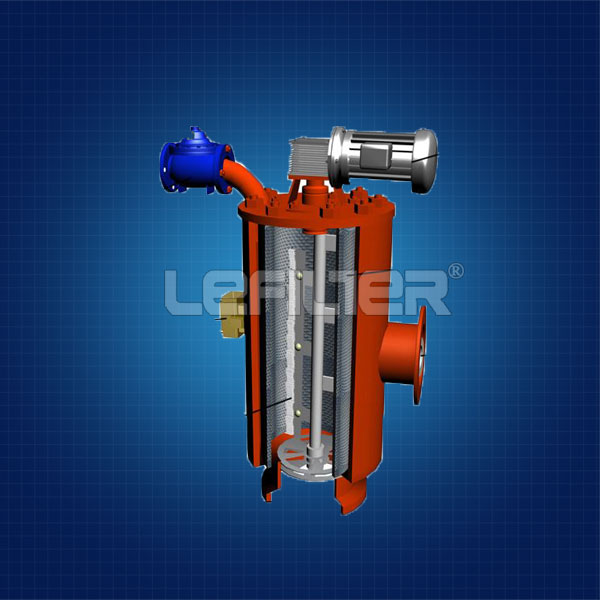

Auto Self Cleaning Strainer

Introduction:Applicable Industries ofAutoSelfCleaning Strainer: Water treatment steel pulp and paper miningpetro-chemical precision machining municipal irrigation etc.. channel the gear motor will stop and the next element is cleaned. Typical Ap

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Applicable Industries of Auto Self Cleaning Strainer:

Water treatment, steel, pulp and paper, mining,petro-chemical, precision machining, municipal, irrigation etc.. channel, the gear motor will stop and the next element is cleaned.

Typical Applicable Liquids:

Groundwater, seawater, freshwater, reservoir water, pond water, cooling circulating water, freezing water, high and low spraying water, squirt water, heat exchanging water, sealing water, bearing cooling water, oil wells injection water, recycled process water, machining coolant, cleaning agents, cleaning water, etc..

Filtration Function:

Remove large particles, purify liquids, protect key equipment Filtration type: Back-flushing filter, automatic continuous online filtration

Auto Self Cleaning Strainer Main Specification

|

Sub-series Series |

XFS Series, XFM Series, XFT Series |

|

Applicable Liquid |

Water and liquid of low viscosity(<40cps), contaminant<300ppm |

|

Lowest Working DP |

Differential pressure between the outlet and discharging outlet >0.15MPa |

|

Filtration Rating |

50-2000μm |

|

Design Pressure Class |

0.6MPa/1.0MPa/1.6MPa/2.0MPa |

|

Design Temperature |

0-95°C |

| Flowrate Range | 17-8000m3/h |

| Filter Area | 4970cm2-89530cm2 |

| Self-cleaning DP | 0.05MPa-0.07MPa |

| Control System | Parallel control of differential pressure and time |

| DP Instrument | Differential pressure transmitter, differential pressure switch |

| Gear Motor |

120W, three phase, 380V, protection class IP55, CCWU |

|

Inlet and outlet size |

2"-24" |

|

Connection Standard |

flange,HG20592-2009(Standard design), HG20615-2009(ANSI B16.5 compatible) |

|

Filter Element |

V-SLOT series slotted screen, material 316L/SuperDuplex/Ti2 |

|

Wet Part Material |

304/316L/CS, special material available (such as 904L,duplex S.S.) |

|

Inner Lining |

Epoxy, PA11 for CS Housing or special anti-corrosion requirement |

|

Housing Sealing Material |

NBR(Standard/VITON(FKM) |

|

Discharging Valve |

Pneumatic stainless steel valve or butterfly valve, protection class IP65 |

|

Facility Supply |

Compressed air: clean and dry, 0.4-0.6MPa, 380V AC, 24V DC |

Please fill in your procurement needs and contact information