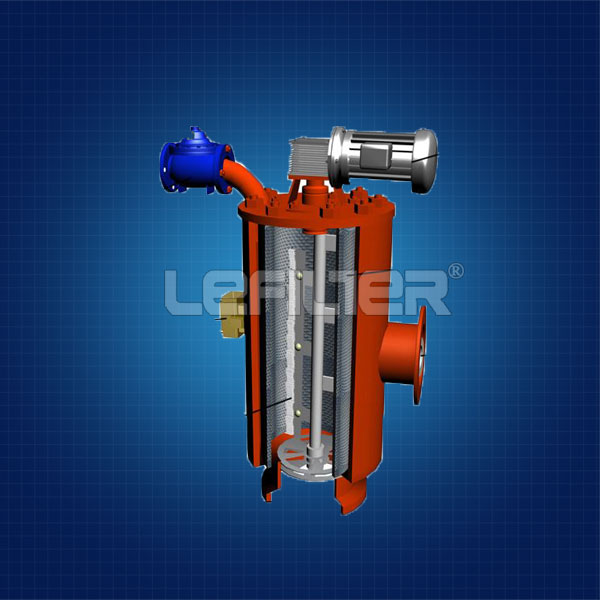

Automatic Pulse Jet Candle Filter

Introduction:Automatic Pulse Jet Candle Filter Design features of automatic back flushing filter The SS cartridge automatic backwash filter adopts automatic-cleaning and internal mechanical structurerealize the complete function of back flushingwhich

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Automatic Pulse Jet Candle Filter

Design features of automatic back flushing filter

The SS cartridge automatic backwash filter adopts automatic-cleaning and internal mechanical structure,realize the complete function of back flushing,which could completely remove the intercepted impurities on the screen,cleaning without dead ends with flux attenuation,which ensure the filtration efficiency and long service lifespan.

The filtration device adopts stainless steel 304 and SS316L as the wedge screen,with high strength, high precision,corrosion resistance,the filtration degree could reach 25 micros.

Few fragile components,no consumptive material,low cost for maintenance and easy management.

Control system is sensitive and accurate operation,in this case, we could flexible adjust pressure difference and time setting as per the different source of raw water and filtration degree.

During the processing of back flushing,all screens will be back flushed one by one,which could ensure the screen is safe and high efficiency,and will not affect other screens to continue filtering.

This filter is of compact and reasonable design,small occupation and flexible and convenient for installation and moving.

attention

| Applicable Liquid | Water and liquid of low viscosity(<40cps), contaminant<300ppm |

| Lowest Working DP | Differential pressure between the outlet and discharging outlet >0.15MPa |

| Filtration Rating | 50-2000μm |

| Design Pressure Class | 0.6MPa/1.0MPa/1.6MPa/2.0MPa |

| Design Temperature | 0-95°C |

| Flowrate Range | 17—8000m³/h |

| Filter Area | 4970cm²-89530cm² |

| Self-cleaning DP | 0.05MPa—0.07MPa |

| Control System | parallel control of differential pressure and time |

| DP Instrument | Differential pressure transmitter, differential pressure switch |

| Gear Motor | 120W, three phase, 380V, protection class IP55, CCWU |

| Inlet and outlet size | 2"—24" |

| Connection Standard | flange,HG20592-2009(Standard Design), HG20615-2009(ANSI B16.5 compatible) |

| Filter Element | V-SLOT series slotted screen, material 316L/SuperDuplex/Ti2 |

| Wet Part Material | 304/316L/CS, special material available (such as 904L,duplex S.S.) |

| Inner Lining | Epoxy, PA11 for CS Housing or special anti-corrosion requirement |

| Housing Sealing Material | NBR(Standard/VITON(FKM) |

| Discharging Valve | Pneumatic stainless steel valve or butterfly valve, protection class IP65 |

Contact information:

Name:Steven

Skype/Email:sales07@lefilter.com

Phone/WhatsApp:0086-18568229226

Please fill in your procurement needs and contact information