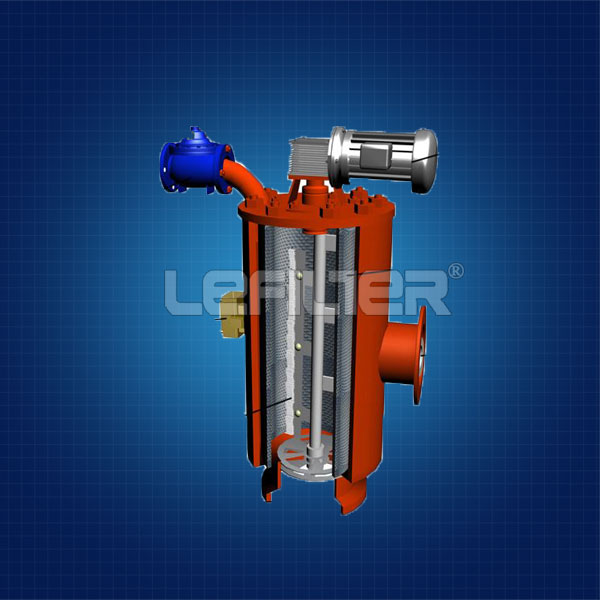

LFA-100 Self-cleaning filter Chemical, food and beverage, sewage treatment

Introduction:Users can choose a self - cleaning filter with a filtration accuracy ranging from 50 to 5000 microns. It features a large filtration area and high dirt - holding capacity, and can be customized according to actual working conditions. The cleaning method is straightforward. By monitoring the cleaning cycle, automatic cleaning and discharging can be achieved, and all parameters in the automatic filter control system are adjustable. Moreover, it is equipped with motor overload protection, which can effectively safeguard the motor.

We're here to help:

Easy ways to get the answers you need.

Product parameter:

LFA-100 Brush type self-cleaning filter

It features a compact yet robust construction. The main body houses a precision - made filter element, around which a specially designed brush assembly is installed. The filter element is engineered to capture particles with a high degree of accuracy, ensuring that only clean fluid passes through.

1.Details

| Parameters | Details |

| Filtration Accuracy | 50 - 1000μm (Customizable) |

| Working Pressure | 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa |

| Body Material | Stainless Steel, Carbon Steel with Anti-corrosion Treatment |

| Motor Power | 0.18KW, 0.37KW, 0.55KW, 0.75KW, 1.5KW |

| Structure Form | L Type (Y Type, F Type can be customized) |

| Applicable Temperature | -10 - 90℃ |

| Backwash Time | 60 - 120s (Adjustable) |

2. Working Principle

During normal operation, the fluid enters the filter from the inlet. As it flows through the filter element, impurities and contaminants are trapped on the surface of the element. When the pressure differential across the filter reaches a pre - set value or a specific time interval has elapsed, the self - cleaning process is activated. The motor drives the brush to rotate, which scrubs the surface of the filter element. Simultaneously, a valve opens, allowing the loosened impurities to be flushed out of the filter through the port. This self - cleaning mechanism ensures continuous operation without the need for manual intervention, minimizing downtime.

3. Key Features

High Filtration Precision: It can achieve a filtration accuracy of up to [X] microns, effectively removing fine particles and ensuring high - quality filtrate.

Automatic Self - cleaning: The self - cleaning process is fully automated, reducing labor costs and improving operational efficiency.

Low Maintenance: With its durable construction and self - cleaning function, the LFA - 100 requires minimal maintenance, resulting in long - term cost savings.

Energy - efficient: The motor used in the self - cleaning process consumes relatively little energy, making it an environmentally friendly choice.

4. Applications

This filter is widely used in various industries. In the industrial sector, it is suitable for applications such as cooling water systems in power plants, industrial process water filtration in manufacturing plants, and water treatment in chemical industries. In the commercial field, it can be applied in building water supply systems, swimming pool filtration, and irrigation systems in agriculture, providing reliable and efficient filtration solutions for different scenarios.

In summary, the LFA - 100 Brush type self - cleaning filter offers a reliable, efficient, and cost - effective solution for filtration requirements across a wide range of industries.

What can I help you?

What is it for?

Water treatment: used for industrial circulating water, sewage treatment, seawater desalination, etc.

Petrochemical: filter crude oil and chemical liquids, and protect equipment.

Food & Beverage: Ensure the purity of the water used in the process.

Please fill in your procurement needs and contact information