Smooth Side Inside SS Wedge Wire Filter Element

Introduction:Smooth Side Inside SS Wedge Wire Filter Element Product Desc

We're here to help:

Easy ways to get the answers you need.

Product parameter:

Smooth Side Inside SS Wedge Wire Filter Element

Product Description of Smooth Side Inside SS Wedge Wire Filter Element,

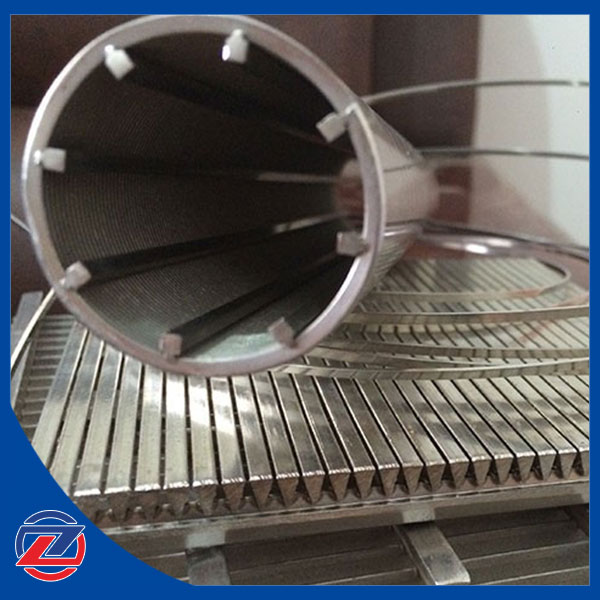

Smooth Side Inside SS Wedge Wire Filter Element With The Profile Inside Lengthways

* Filter element

* Profile inside legthways

* Slot size 0.25mm (more sizes are available)

* Filtering direction: From inside to outside

* OD: 76mm

* Length: 700mm

* Material: 316L

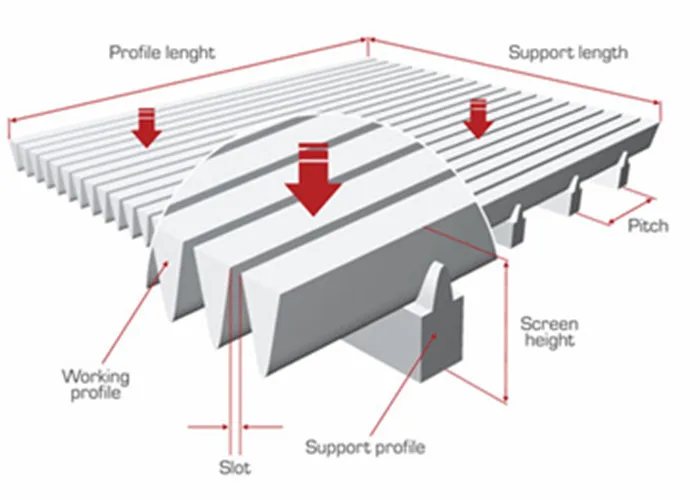

Screen Details

Wedge Wire Screen Filter Structure- FITO 2

The filtration direction of this structure is from inside to outside, The wedge wire is inside lengthways.

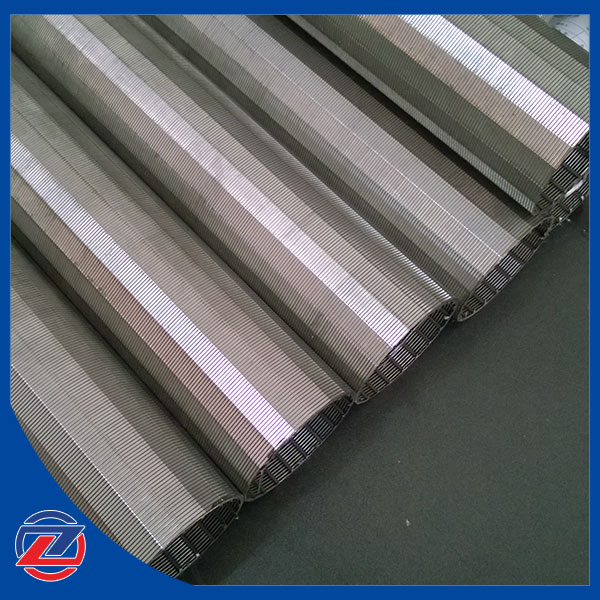

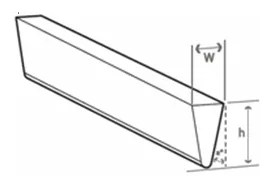

Wedge Wire Screen Profile Wire

12S/ W1*H2mm

10S/ W0.75 *H1.425mm

18S/ W1.52 *H2.54mm

Material: SS304 /316L

Shape: Wedge Wire

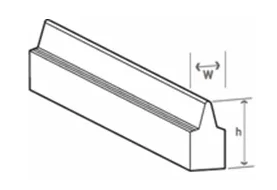

Wedge Wire Screen Support Rod

Q25 / W2*H3mm

Q22 / W2*-2.3mm

Matieral: SS304 /316L

Shape: Square

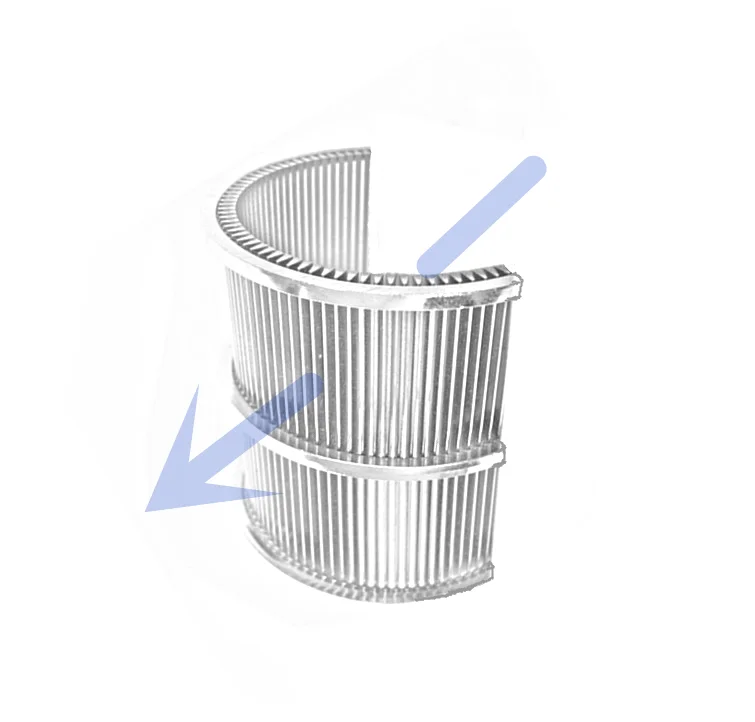

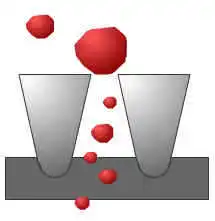

V slot Feature

Introduction of wedge wire screen and v shape filtering slot features

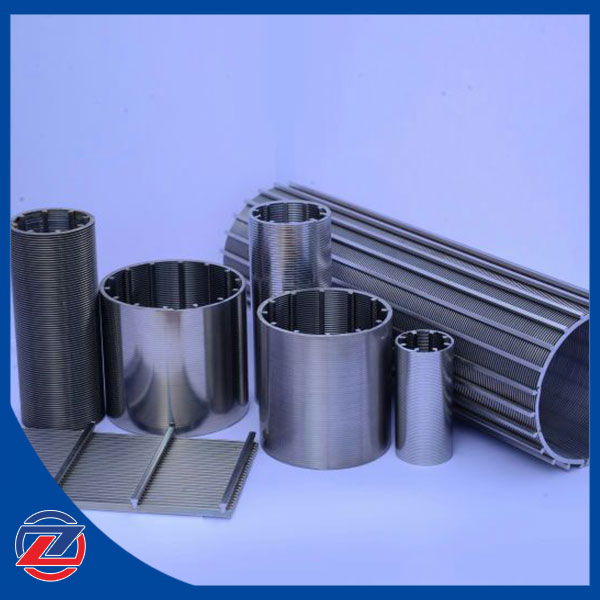

Wedge wire screen is the widely using screen for filtration and separation in liquid/gas, mining, food, water wasting, and so on. Wedge wire screen have flat type, cylinder type, slope type and basket type. So Wedge wire screen is called as flat welded screen panel, cylinder wedge screen and sieve bend screen. According to the weaving type, they are also called woven wedge wire and welded wedge wire such as crimped wedge wire, welded wedge screen panels.

Wedge wire screen are producing by profile wire and support rods with the materials of galvanized steel, stainless steel and low carbon steel. Wedge wire screen have a lot of applications like using in oil, gas, chemical, food or beverage, mining, waste water management or coal separation.

Schroeder can provide you with a Wedge Wire screen which designed by your own specifications manufactured from either grade 304 stainless steel or grade 316 stainless steel. Length, width, shape and spacing of profile wire are made to meet your special application requirements.

|

Wedge wire screen welded structure provides it with the following characteristics |

High mechanical strength |

|

Freestanding structure |

|

|

Absolute filtration threshold |

|

|

Continuous slots having openings down to 15 μm |

|

|

Increased open surface |

|

|

Anti-clogging surface |

Wedge Wire Screen Filter Element Typical Application Areas

Coal/coke washeries - Seperationn Machine component / Wedge wire screen Filter mesh

Sugar mill- Seperation or Filtration component

Chemical and petrochemical- Hydro treating Filtering element / Filtration component

Soda ash plants- Seperation or Filtration component

Fertilizer plants- Seperation or Filtration component

Cement plants- Seperation or Filtration component

Solvent extraction plant- Filtering element / Filtration component

Effluent/water treatment plants - Filtering element / Filtration component

Stone quarrys - Seperation or Filtration component

Paper and pulp industries - Seperation or Filtration component/ Self-cleaning Single Filter

Food processing industries- Seperation or Filtration component / Back flushing cleaning Filter

Beer & Beverage Industries -Filtering Element or FitrationElement

Petroleum Refining

The wedge wire screen filter element are mainly used in petroleum refining , gas processing, petrochemical production industries.

Water treatment

More and more water treatment companies now use these wedge wire screen filter element to do water treatment plant. Some are made into filtering nozzle, some made into filter cartridge. The wedge wire screen have an advantage, that the special structure makes the filter element easily to clean by back flushing.

Beer Diatomite Filtration element

The wedge wire screen filter element can be made into candle filters which are widely used in beer and beverage filtration .Our Schroeder Technology filter element are perfect round with smooth surface, So that the catalyst media can be everagely plated.

Please fill in your procurement needs and contact information