Coalescing separation filters are used in oil-water separation systems, mainly separating oil-water mixtures, suspensions, emulsions, etc. The use

process of coalescence separation filter in the system is divided into:

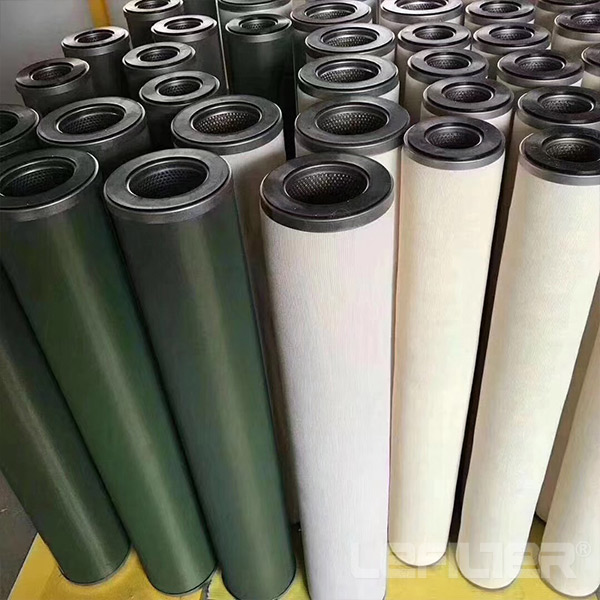

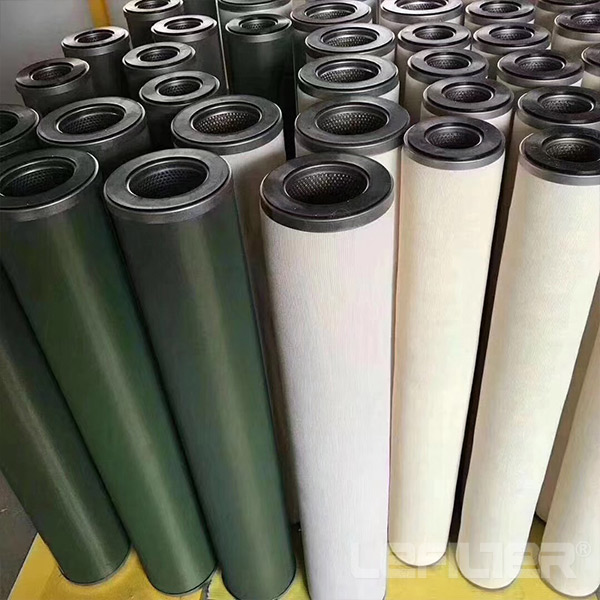

Solid-liquid separation - demulsification - coalescence - separation - adsorption. In this system, the greater the number ratio of coalescing filters and

separation filters, the better the coalescing effect and the faster the separation speed. At present, two water treatment filter elements have been

standardized.

The coalescing filter element has the dual function of filtering impurities and coalescing moisture in aviation kerosene, and is an important functional

element of fine filters.

It can meet the needs of a wide range of fine filters used in stationary mobile refueling facilities.

1. The filter paper with multi-layer composite structure has high filtration accuracy;

2. Carefully set and specially treated glass fiber layer has good coalescing effect;

3. High flow density and reduced size of fine filter;

4. Large capacity and long service life;

5. Complete specifications and varieties, can meet the needs of various fine filters.

The coalescence separator is mainly designed for liquid separation, and it contains two filter elements, namely coalescence filter element and separation filter element. For example, in an oil-water removal system, after oil flows into the coalescer, it first flows through a coalescer filter, which filters out solid impurities and coalesces tiny water droplets into larger droplets. Most of the coalesced water droplets can be separated and removed from the oil by their own weight and settled in the sump tank. The oil then flows through the separation element, where the water is further separated due to its good lipophilic and hydrophobic properties. The oil enters the lower part of the filter housing through the inlet pipe and then flows the filter element from the outside to the inside. At this point, the coarse particles will immediately settle down and be released by the blowdown valve, while the smaller particles will be intercepted by the filter element.

As the amount of oil processed increases, contaminants deposited on the filter can cause the pressure differential of the coalescer to rise. When the pressure difference rises to 0.15 MPa, it indicates that the coalescence filter element is blocked and should be replaced. The oil flows from the inlet of the coalescence separator into the main tray and then to the main filter element. After filtration, demulsification, water molecule growth and coalescence, impurities are trapped in the primary filter element, and the coalesced beads precipitate in the sedimentation tank. The material of the secondary filter element is hydrophobic, allowing the oil to pass smoothly, while the free water is kept out of the filter element and flows into the sedimentation tank and is discharged through the blowdown valve.

Related products recommend

Coalescence Dehydration Oil Filter

Oil Filter Element

Oil Filter Assembly