Replace EPPENSTEINER(EPE) filter element

In hydraulic systems, EPE filters are extensively employed for removing solid particles and colloid matters, effectively regulating the contamination level of the working medium. This guarantees the safe and efficient operation of hydraulic and lubrication systems. They are primarily used for filtration in the hydraulic systems of rolling mills and continuous casting machines, as well as various lubrication equipment. Furthermore, they are utilized in product separation and recovery during oil refining and chemical production, as well as water injection in oil fields and natural gas dust particle filtration.

The use of these filters spans across rolling mills, continuous casting machine hydraulic systems, various lubrication equipment, and in the processes of product separation and recovery in oil refining and chemical production.

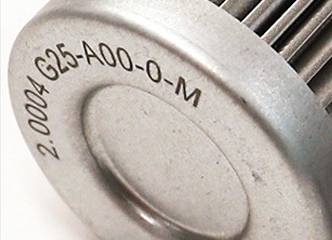

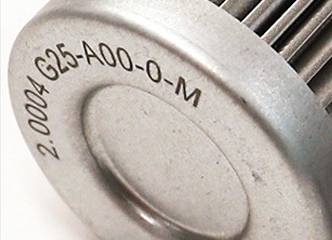

Technical Specifications:

Filtration Accuracy: 2-25μm

Operating Temperature: -30℃~+100℃

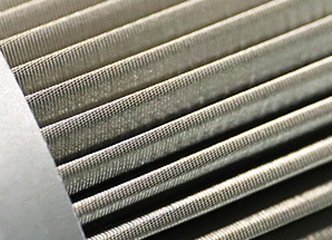

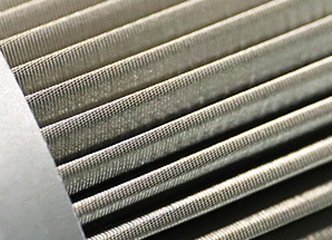

Filter Material: Stainless Steel

Filtration Medium: Hydraulic oil, lubrication oil, emulsion

Seal Material: Nitrile rubber, Fluororubber

Nominal Pressure: 0.6~42Mpa

Filter Material: Stainless steel mesh filter material, metal fiber filter material, wool, glass fiber, water-absorbing glass fiber, filter paper

Replacing EPE filters involves looking for alternatives that can offer the same level of filtration accuracy, durability, and functionality. These alternatives should have similar or better specifications with the capacity to withstand various conditions and should be compatible with hydraulic oil, lubrication oil, and emulsion. Their ability to handle varied pressure levels while offering the same filtration excellence is also of utmost importance.

Such substitutes should also possess acceptable sealing properties to avoid potential leakage issues that could compromise the safety and efficiency of the systems they serve. Lastly, the choice of filter material should equally match the performance offered by EPE filters, ensuring optimum filtration and extended service life.

In essence, the quest for alternatives to EPE filters should focus on exploring options that match or even outperform the technical features and functionalities of EPE filters. This would ensure that such substitutions contribute to improved performance, optimizing the efficiency and productivity of the various systems in which they are installed.