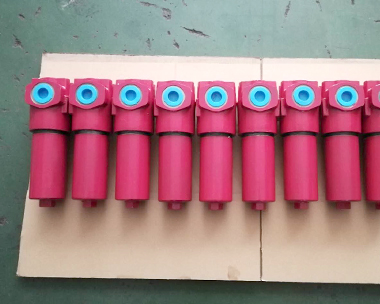

Replace HYDAC filter element is an indispensable part of the pipeline series that conveys media. The filter element is usually installed in the inlet filter of the hydraulic system to filter out metal particles and pollutants in the fluid medium, which can protect the normal operation of the equipment. When the fluid enters the filter, its impurities are blocked, and the clean filtrate is discharged from the filter outlet.

When cleaning is needed, the filter element can simply be removed from the filter, treated with industrial liquid, and then reinstalled. The performance parameters of the HYDAC replacement filter have reached the level of similar foreign filters and can completely replace the use of HYDAC filters.

The application ranges include thermal power and nuclear power, electronic industry, petrochemical industry, and railway internal combustion engine filtration, among others.

Technical parameters consist of:

Material: Stainless steel woven mesh, sintered mesh, iron woven mesh;

Filter material: Fiberglass filter paper, synthetic fiber filter paper, wood pulp filter paper.

Features: High flow, high filtration efficiency and a wide range of applications.

Filtration accuracy: 1-100μm; working temperature: -30℃~+100℃;

Core material: Stainless steel flange; seal surface: FF, RF, MFM, RJ, TG.

Working medium: General hydraulic oil, lubricating oil, phosphate ester hydraulic oil, emulsion, water-ethylene glycol.

Gasket/Seal ring: Silicone rubber, ethylene propylene rubber, butene rubber, fluoro rubber.

Examples of Models include: 1.0060RBN/HC, 2.0165RBN/HC, 3.0080MA*BN3HC.

Utilizing these replacement filter elements ensures the optimal functionality and longevity of your critical equipment and machinery while ensuring operational efficiency and cost-effectiveness. They offer equivalent, if not superior, performance to their HYDAC counterparts, thereby delivering excellent value for the investment.