In an age where maintaining clean and hygienically optimal environments is crucial, coping mechanisms to battle airborne particles are imperative, none more so than the Pocket Bag Filter. Employed predominantly in HVAC systems, these filters eliminate dust and other particulate matter, ensuring the air remains as clean and safe as possible. This distinctively specialized product offers a multitude of advantages that makes it an unparalleled choice in various realms of operation.

The Pocket Bag Filters, intricately designed to cater to specific industrial needs, are primarily used to eradicate 1-5µm particles from ambient air. This holds particular significance in industries such as pharmaceutical, food, textile, medical machinery, petrochemical, micro-electronics, as well as in large facilities such as car factories, hospitals, and airports. The caution and purity demanded by these fields make the product indispensable.

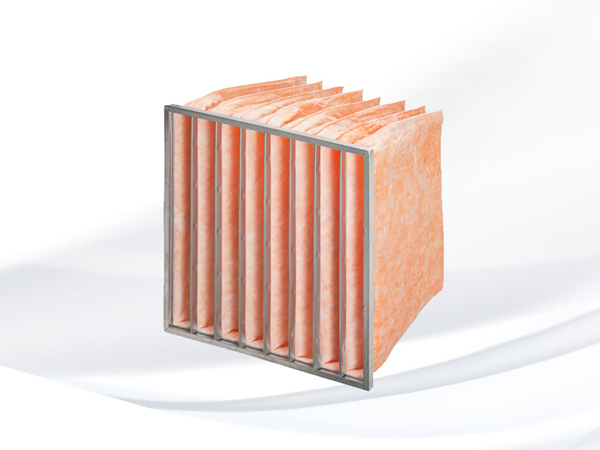

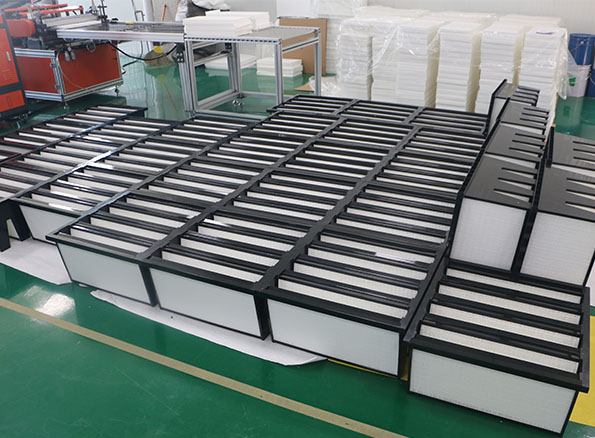

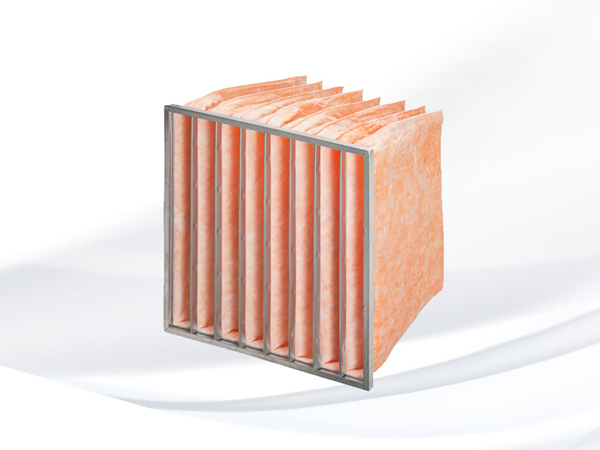

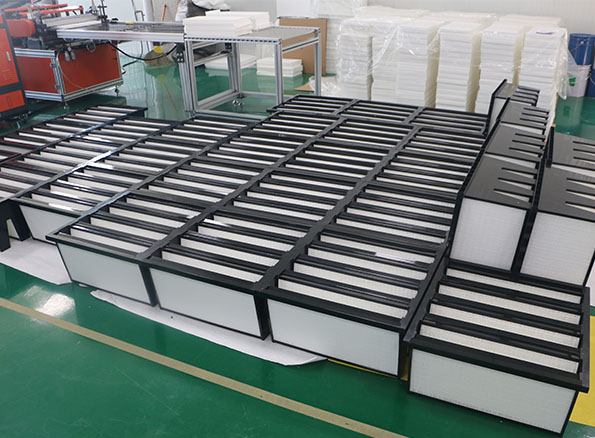

The structural integrity and longevity of the Pocket Bag Filters are guaranteed by its robust build. The filters' framework is meticulously crafted from aluminum or galvanized steel, providing both strength and durability. Their pockets, made from either synthetic fiber or fiberglass, secure a high degree of filtration efficacy. These perfect blends of varying materials ensure a multi-tiered filtration process and a longer service life - up to an impressive 8000 hours.

An exceptional feature of the Pocket Bag Filters is their large dust holding capacity. This feature combined with their low-pressure resistance property makes them an economical and energy-efficient choice for various applications. Additionally, the filters are washable for repeated use, further extending their useful life and providing a practical solution for businesses aiming for sustainable options.

As the Pocket Bag Filters are designed with diverse operational environments in mind, they come in several common specifications. These variations may include different dimensions, pocket numbers, and filter class suited to particular needs. In the form of WHDPockets Nos./ Filter Class, like 5953406006P/F5, companies can customize according to their specific work conditions. Additionally, the frame thickness of the filters can also be selected based on the operational demands.

In conclusion, the Pocket Bag Filters offer a versatile yet specialized solution to maintaining working environments' cleanliness. Their robust construction, superior filtration capabilities, extended service life, and customizable qualities make them desirable for diverse industry requirements. The pertinence of clean air quality cannot be overstated, especially in today's world. With Pocket Bag Filters, industries and facilities are well equipped to meet clean air requirements, ensure safety, and continue to deliver quality work while safeguarding their environment.

The application of Pocket Bag Filters within the realm of medical equipment is vast and intertwined with the fundamental goal of ensuring and maintaining sterile environments. Here are just a few of its key applications:

Air Purification: In hospital HVAC systems, these filters are used as final filters to purify the air of dust and harmful microorganisms, ensuring the cleanest possible environment for patients. This is particularly crucial in critical areas such as operating theatres, ICUs, and labor rooms, where airborne contaminants must be kept to an absolute minimum.

Medical Machinery: Many medical machines, such as those used for imaging (MRI, CT scanners), dialysis units, and pulmonary function testing devices, utilize these filters to ensure the ambient air does not contribute to any machine malfunction due to the presence of unfiltered particles in the air.

Pharmaceutical Preparation: In pharmaceutical labs where medication and medical supplies are prepared, these filters help maintain a dust-free environment to uphold the strict sanitary standards in these preparation areas.

Biosafety Cabinets & Cleanrooms: Pocket Bag Filters are pivotal in filtering the inflow and outflow air in high-risk areas like bio-safety cabinets and clean rooms, protecting the environments from harmful microorganisms and particulates.

Pre-Filter for HEPA Filters: Due to their excellent dust holding capacity, these filters are often used as pre-filters for High-Efficiency Particulate Air (HEPA) filters, extending the life of these more expensive, highly efficient filters.

By filtering out larger, detrimental particles, Pocket Bag Filters help in keeping the medical environment, equipment and personnel safe from airborne threats, thus enabling the provision of the best possible patient care.

The presence of the Pocket Bag Filter in medical equipment has a profoundly positive impact on air quality, specifically in the following ways:

Elimination of Airborne Contaminants: These filters proficiently eliminate dust, bacteria, mold spores, and other particulate matter from the air, thereby preventing their spread within sensitive medical environments.

Preventing Cross-Contamination: By trapping and eliminating microbes from the air, the filter plays a critical role in preventing cross-contamination among patients and medical devices.

Maintaining Sterile Environments: In areas necessitating high sterility levels such as operating theaters, ICUs, and pharmaceutical labs, the filters help maintain a sterile airspace, reducing the risk of infections or contaminations.

Enhancement of HVAC Efficiency: They improve the efficiency of HVAC systems by preventing dust and particle build-up, thereby maintaining the air quality and extending the HVAC system's lifespan.

Protecting Medical Machinery: Filtered air can protect sensitive medical machinery from damage that can be caused by dust or particulates. This ensures the machines' longevity, optimal functioning, and accurate results.

Patient Health and Recovery: Cleaner air contributes to better patient health, lowering risks of respiratory issues or infections, and aids in faster recovery.

Protection for Healthcare Professionals: By improving air quality, the filters safeguard healthcare workers from potential airborne diseases or allergens, creating a safer work environment.

In conclusion, the impact of Pocket Bag Filters on air quality in medical settings is substantial. They are indeed instrumental in creating safer and cleaner atmospheric conditions, optimizing equipment performance, and boosting patient recovery and health.

Pocket Bag Filters play a vital role in safeguarding healthcare professionals from airborne diseases in numerous ways:

Capture of Airborne Particles: The densely packed fibers in these filters can efficiently trap and hold a wide variety of airborne particles, including bacteria, viruses, and fungal spores, reducing their concentration in the air breathed by healthcare workers.

Preventing Spread of Diseases: By capturing these pathogenic particles, the filters limit the spread of airborne diseases within healthcare facilities, reducing the risk of healthcare workers contracting these illnesses.

Mechanical Filtration: The design of these filters often incorporates multiple layers of material with graded pore sizes. This 'mechanical filtration' approach physically removes pathogens from airflow by trapping them in the filter media, preventing them from being inhaled by healthcare professionals.

Improved Indoor Air Quality: Through high-efficiency filtration, these filters significantly enhance the indoor air quality by reducing the amount of particulate matter, dust, and microbial contamination present in the air. This reduces the overall occupational health risks for healthcare workers.

Continuous Protection: Pocket Bag Filters are designed to operate continuously, offering round-the-clock protection for healthcare professionals working in medical facilities.

Compatibility with HVAC Systems: These filters are often designed to be compatible with existing HVAC systems, allowing for widespread, efficient filtration of air within hospitals and clinics without needing to retrofit or upgrade existing infrastructure.

In sum, the function of Pocket Bag Filters transcends beyond the simple act of trapping particles. Their efficient filtration capacity acts as a pivotal line of defense, protecting healthcare professionals from the risk of airborne infections.