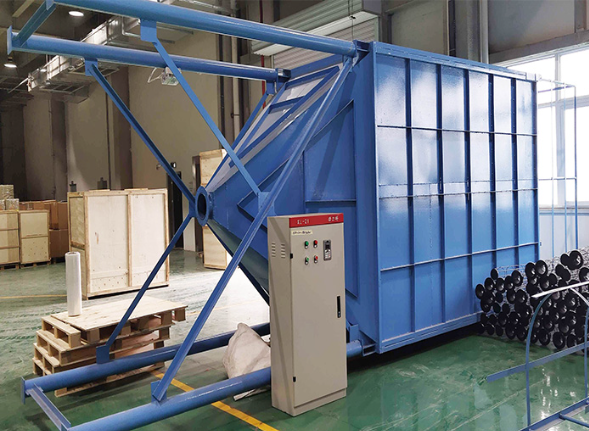

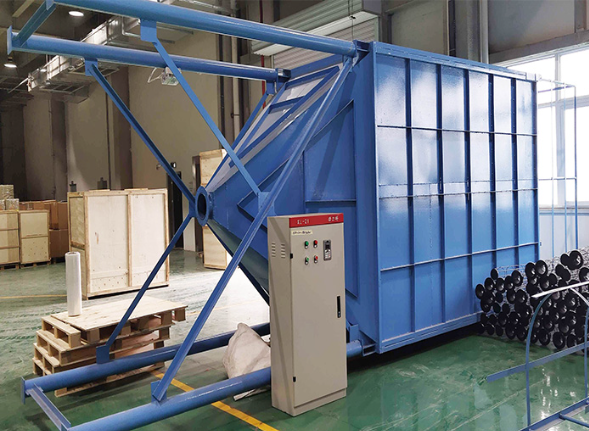

Baghouse dust collectorsare using needle felt bags for filtering and reverse pulse compressed air to clean filters.

After the dust loading gas inters the filter chamber, the dusts are filtered on the surface of bags, and clean air is discharged from the top of the filter bags.

When the differential pressure across the bags reaches a certain value, the compressed air will be blown into the center of bags through nozzles, leading the surrounding air into the bags.

The expansion force inside the bags will blow off the dusts on the bag surfaces.

The bags restore their pressure drop and recover the filtration performance.

Applications scope

Cement, Woodworking,Chemical, Foundry, Furnace, Grain, Lime, Asphalt, Rubber, Glass, Plastic, Mineral, Ceramics, Stone crushing, Battery, Pigment, Abrasive blasting.

Filtration media

air particles, impurities, etc.

Working Principle

The dirty air enter the system through the inlet and pass through the filter bags.

Due to the use of baffle plate, the heavy particles fall down into the hopper, the lighter particles get deposited on the exterior surface of the filter bags, only allowing the clean air pass through the filter bags up to the clean plenum. The clean air is discharged from the outlet. This is the general process take place in this system.

When a certain level of deposited dust is reached on the filter bag, a pressure is created, and it is detected by the gauge fitted on the machine. And this starts the process of cleaning of the filter bags.

Air stored in the reservoir is released which is carried by the blowpipes.

The high-pressure air is released into the filter bags one row at a time.

The air passing through the filter bags releases the deposited dust and clean the bag, the dust then fall off into the hopper. This process takes place at regular intervals of time, and this allow the filtration process runs smoothly. This is how a pulse jet dust collector works.

Product Advantages

Baghouse dust collector:

The use of sub-chamber air-stop pulse jet cleaning technology overcomes the shortcomings of conventional pulse dust collectors and sub-chamber back-flushing dust collectors.

Safe and reliable operation:

The maintenance and replacement of bags can be carried out in different rooms under the normal operating conditions of the system without stopping the system fan.

Long service life:

The filter bag keel adopts polygonal shape, which reduces the friction between the bag and the keel and prolongs the life of the filter bag.

Air tightness design:

Good sealing performance, excellent inspection Sealing material, coal is used in the production process Oil leak detection, low air leakage rate.

Baghouse Dust Collectors, utilizing advanced needle felt bags and reverse pulse compressed air technology for superior filtration performance.

As the dust-laden gas enters the filter chamber, our needle felt bags efficiently capture dust particles on their surfaces, while clean air is discharged from the top of the filter bags.

When the pressure across the bags reaches a certain threshold, our reverse pulse compressed air system activates, blowing air into the center of the bags through nozzles. This action leads to the surrounding air being drawn into the bags, creating an expansion force that effectively dislodges dust particles from the bag surfaces.

Thanks to this innovative technology, our baghouse dust collectors quickly restore their pressure drop and recover filtration performance, ensuring continuous and efficient operation for cleaner workspaces and healthier environments.