Cartridge Dust Collector, designed for exceptional performance of air cleaning.

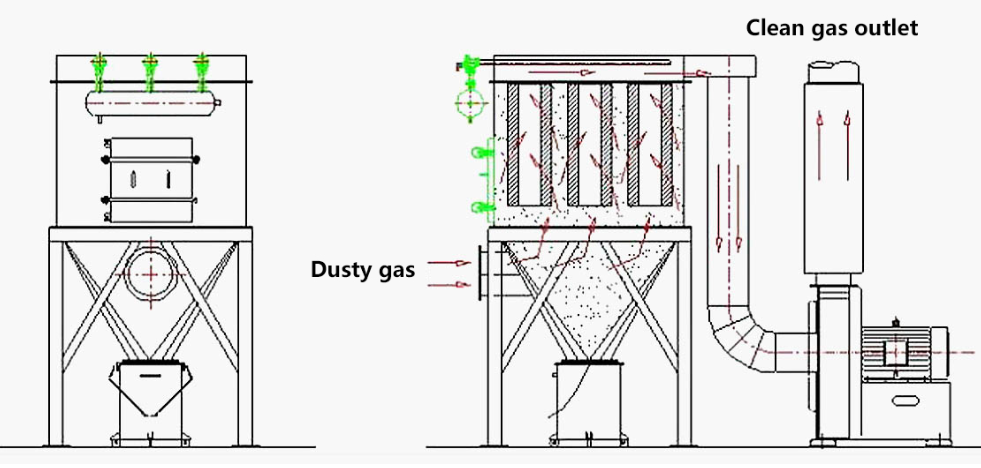

As the dust-laden gas enters the tank through the air inlet, our cartridge dust collector utilizes the negative pressure within the folding filter cartridge to its advantage. The gas is forced through the filter material on the exterior of the cylinder, effectively capturing dust particles. From there, the gas enters the clean air chamber, where it undergoes further filtration, resulting in clean, purified air that is discharged through the air outlet.

The cartridge dust collector is operated under negative pressure. The dust-containing gas enters the tank through the air inlet.

Under the action of the negative pressure in the folding filter cartridge, the gas enters the cylinder through the filter material outside the cylinder,and then enters the clean air chamber, and finally the clean gas is discharged from the air outlet.

Applications scope

Metalworking, Plasma/Laser Cutting, Grinding, Sandblasting, Powder Coating,Shipbuilding, Tobacco, Electricity, Food Processing,Welding and Casting ect.

Filtration media

air particles, impurities, etc.

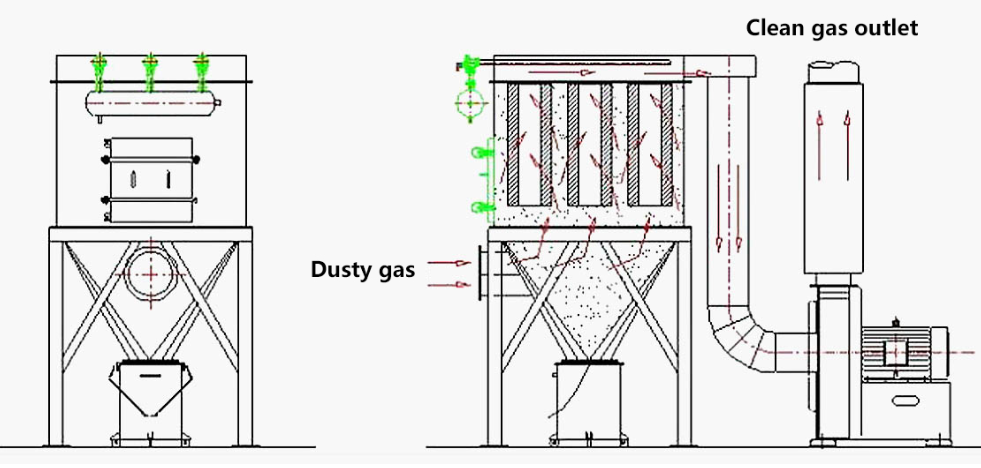

Construction

The main body is divided by a

The main body is divided by a tube sheet into two parts.

The lower body is called dirty air plenum, the upper body is called clean air plenum.

The lower body includes an inlet which is connected to flexible suction pipes which carry the dirty air from the source, At the bottom is the hopper which is fitted with a rotary air lock system for continuous discharge of the dust particles.

The upper body includes the main filtration system.

It includes the rows of filter cartridge, each cartridge is attached to the tube sheet.

Above the tube sheet in the upper body is the cleaning system of the machine. It includes the rows of blowpipes, each blowpipe is drilled with holes and connected to the air reservoir which has solenoid valveattached to it.

The upper body also includes the outlet which is connected to a series of pipe, used to carry the filtered air.

Working Principle

The dirty air enter the system through the inlet and pass through the filter cartridge.

Due to the use of baffle plate, the heavy particles fall down into the hopper, the lighter particles get deposited on the exterior surface of the filter cartridge, only allowing the clean air pass through the cartridge up to the clean plenum. The clean air is discharged from the outlet. This is the general process take place in this system. When a certain level of deposited dust is reached on the filter cartridge, a pressure is created, and it is detected by the gauge fitted on the machine. And this starts the process of cleaning of the filter cartridge. Air stored in the reservoir is released which is carried by the blowpipes.

The high-pressure air is released into the filter cartridge one row at a time.

The air passing through the cartridge releases the deposited dust and clean the cartridge, the dust then fall off into the hopper. This process takes place at regular intervals of time, and this allow the filtration process runs smoothly. This is how a pulse jet dust collector works.

Product Advantages

Easy Installation and Maintenance: aviod complicated setups and time-consuming maintenance routines.

High Filter Efficiency: Achieve a remarkable 99% filtration efficiency, ensuring cleaner air and improved indoor air quality.

Pleated Media Design: Our innovative pleated media design maximizes the filter area, enhancing filtration performance.

Low Operating Resistance: With operating resistance as low as 500-800pa, products reduces energy consumption, saving cost while keeping the air clean.

Experience the difference with our product - the ultimate solution for efficient and hassle-free filtration.