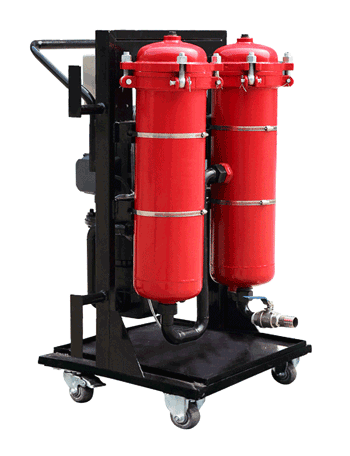

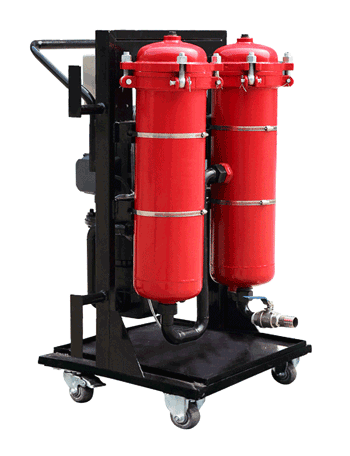

The oil filter truck can be regarded as a high-efficiency filter, and its main purpose is to clean and filter the impurities contained in the oil in the equipment. Throughout the entire process, the core of the oil filter truck's execution is its filtration system. This system contains coarse and fine filter components, which can completely remove impurities in the oil, including solid particles, moisture, gas, etc. Oil filter trucks are usually equipped with inlet and outlet oil pipes and are designed to be easy to move and can be operated without special tools, making the cleaning and replacement of the filter more convenient.

Oil filter trucks can use pressure filtration or vacuum evaporation-pressure filtration methods to remove impurities and impure oil. Oil filter trucks are mainly used to improve the insulation performance of electrical appliance oil, and are also used for filling or regular filtration of oil in hydraulic systems, static pressure systems, lubrication systems and various oil-using equipment.

Here are a few typical applications of oil filter trucks:

In the industrial field, oil filter trucks are ideal tools for filtering liquid metal, narrow groove lubricants or coolants. They can prevent contaminants from entering the product and ensure product quality and stable operation of equipment.

In the field of food processing, oil filter trucks are used to filter and clean edible oil during the frying process, extending the service life of the oil, reducing over-oiling and contamination of the food, and improving the safety and taste of the food.

In the field of automobile repair, oil filter trucks are often used to clean and maintain various hydraulic and lubrication systems, reducing equipment failures and downtime and improving equipment efficiency.

The oil filter truck is undoubtedly a powerful assistant in modern industry. It plays a key role in protecting equipment and improving equipment performance under various circumstances.

The oil filter truck is mainly a piece of equipment that removes particulate impurities and toxic substances from the equipment oil through filtration to ensure the normal operation of the equipment.

Inhalation stage: The internal equipment of the oil filter truck first inhales the equipment oil. This process is generally completed by a special oil suction pump, which not only ensures the smooth suction of oil, but also performs necessary pretreatment of the oil under certain circumstances, such as when the oil viscosity is too high.

Pre-filtration stage: The sucked oil usually needs to go through a pre-filtration before entering the main filtration system. At this stage, large impurities in the oil, such as metal shavings, dust, etc., will be effectively intercepted and removed. Pre-filtration not only helps protect the main filtration system, but also effectively reduces equipment maintenance needs and extends the service life of the filter element.

Main filtration stage: The pre-filtered oil will enter the main filtration system for fine filtration. During this process, the filter element of the composite filter material will deeply clean the oil and remove impurities as small as micron levels, such as tiny metal particles, scale, harmful chemicals, etc. This process will ensure that the cleaned oil reaches the required cleanliness to ensure the normal operation of the equipment.

Output stage: The filtered oil is finally sent back to the equipment. At this stage, clean oil can effectively lubricate the equipment and ensure the working efficiency and service life of the equipment.

System detection and control stage: During the working process of the oil filter truck, it is generally equipped with relevant sensors and control equipment to dynamically detect and evaluate the filtration effect. The control equipment will adjust the working mode of the oil filter truck in real time based on the detection data to ensure that it always operates in the best condition.

Advantages of oil filter trucks:

Improve equipment performance: Once the oil in the equipment is contaminated by impurities, dust or chemicals, it may cause equipment performance to decline and accelerate component wear. Using an oil filter truck to clean the oil regularly can greatly reduce equipment degradation caused by pollution, ensure the normal operation of the equipment, and improve the performance and efficiency of components.

Extended oil and equipment life: This is very important. The oil filter truck can remove impure substances in the oil and restore it to cleanliness, which not only extends the service life of lubricating oil, hydraulic oil, etc., but also maintains the long-term operation of the equipment, thereby extending the overall life cycle of the equipment.

Reduce maintenance and operating costs: Traditional methods require you to replace oil and filters regularly, which will add additional operating and maintenance costs. But by using an oil filter truck, you can reduce similar costs. At the same time, because the oil filter truck usually uses an efficient and durable filter element, it has a long service life and does not need to be replaced frequently.

Environmental protection: Instead of discarding the waste contaminated oil directly, it is better to re-filter it to remove the harsh substances in the oil and put it into use again. This avoids the discharge of oil, reduces waste output, and helps environmental protection.

Safe and reliable: Most modern oil filter trucks are equipped with advanced sensors and control systems to monitor and alarm the working status of the equipment in real time to ensure the safety and reliability of the equipment.

Ease of use: Although the work process of the oil filter truck is complex, the manufacturer's design philosophy is to make it simple and understandable for end users to operate it. Therefore, the operation of the oil filter truck is usually very intuitive, greatly simplifying the operation process and making it easy for users to get started.

Wide application: The application fields of oil filter trucks are very wide. It can find its place in a variety of different industries, including but not limited to machinery manufacturing, petrochemical industry, ships, power systems and others that require the use of various types of oils. field, it can effectively prevent equipment failures and improve equipment operating performance.

The main components of the oil filter truck are modularly designed to better meet various work needs. The functions and effects of each component will be introduced in detail below.

Primary filter: The primary filter is the first module in the oil filter truck that comes into contact with impure oil. It is usually a rough mesh or filter. Its main function is to filter out larger solid particles in the oil, such as metal shavings. , sand, etc. The purpose of this is to prevent these large particles from entering the oil filter device and oil pump, which may cause wear to their internal parts. The primary filter is easy to use and easy to clean and replace.

Vacuum evaporator: The vacuum evaporator is a sealed evaporation device that heats oil to form fine oil droplets under the action of atmospheric pressure. This process helps make it easier for water and gas in the oil to separate from the oil. It is an important tool for eliminating moisture and gas contamination in oil.

Oil pump: The oil pump is the core component of the oil filter equipment. It is mainly used to provide sufficient hydraulic pressure for the entire system so that the oil flows through each processing module. It must be able to withstand various high pressures and work stably under such pressures, and must also have high corrosion resistance.

Filtration device: The main task of the filter device is to remove tiny impurities in the oil. These tiny impurities may include metal particles, dust, sediments, etc., which are crucial to the stable operation of the equipment. Filtration devices are typically made from high-efficiency filter materials that effectively capture particles of all sizes.

Condenser (i.e. condenser): After the oil is processed by the vacuum evaporation tank and the moisture and gas in the oil are separated in the form of steam, the steam will enter the condenser for condensation. This is a cooling process that recondenses the vapor into liquid water and gas, which are then vented from the system.

Vacuum pump: The vacuum pump is responsible for creating a vacuum environment within the entire filtration system, which can speed up the work efficiency of other components. Especially during the evaporation and condensation processes, the vacuum environment can significantly increase the separation and discharge speed of moisture and gas in the oil.

Each module has an important impact on the overall performance of the oil filter truck, which is why the oil filter truck can more effectively deep clean the oil and make a more efficient contribution to protecting the equipment.

The hydraulic filter, as the core part of the filtration device of the oil filter truck, is complex enough in design because it needs to handle a large number of tiny impurities of different types and sizes.

Particle filtration: The main function of the hydraulic filter is to filter out solid particles, such as metal shavings, dust and other tiny impurities in the lubricating oil. This process is mainly achieved through physical adsorption and interception. There are one or more filter elements inside the filter. These elements are made of filter media of different sizes and types. When the oil flows through, particles of different sizes will be trapped and adsorbed by the tiny pores in the media.

High-precision filtration: The filter element material inside the hydraulic filter is usually designed to be very fine, using advanced microporous filter materials to ensure high-precision filtration of the oil. The micropores of this material can filter particles down to micron or even nanometer levels to ensure that the continuously flowing oil remains in a clean and stable state.

Different filter materials: In some special applications, oil filter trucks may need to remove hydrophobic particles in the oil or impurities with moisture on the surface of the particles. In this case, it is necessary to use special hydrophobic filter materials or specially designed polymer materials for coalescence and demulsification.

Multi-stage filter network: A filter device with certain capabilities usually combines various filter elements to form a complex filter network. This network design allows the oil to undergo multiple filtration and adsorption processes as it flows through, thereby maximizing the removal of tiny impurities.

The design of the hydraulic filter is very clever. It uses the principles of physical adsorption and interception to remove impurities in the oil. It can also achieve certain specific filtration effects through material selection. At the same time, because the internal components of the filter can be replaced periodically, the oil filter truck can always maintain a high filtration efficiency. In addition, some advanced filtering devices also have self-cleaning functions and can perform self-maintenance to extend the service life of the equipment.