What is the cartridge dust collector?

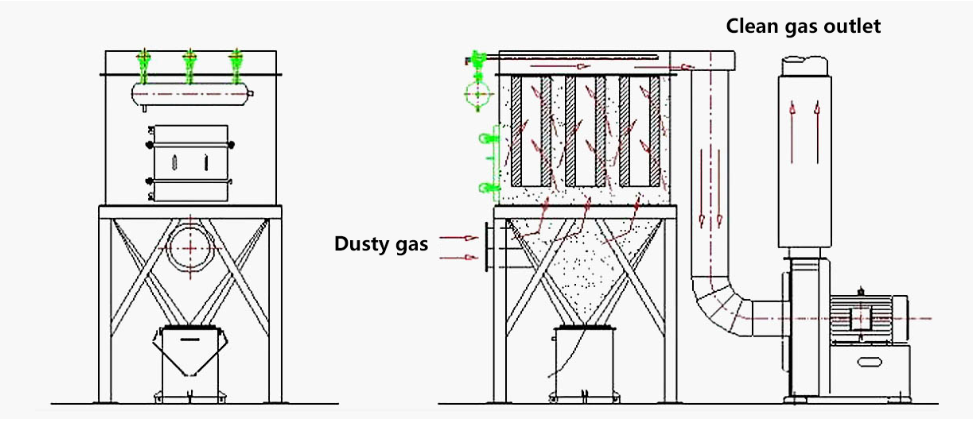

The cartridge dust collector is operated under negative pressure. The dust-containing gas enters the tank through the air inlet.

Under the action of the negative pressure in the folding filter cartridge, the gas enters the cylinder through the filter material outside the cylinder,and then enters the clean air chamber, and finally the clean gas is discharged from the air outlet.

The cartridge dust collector is operated under negative pressure. The dust-containing gas enters the tank through the air inlet.

Under the action of the negative pressure in the folding filter cartridge, the gas enters the cylinder through the filter material outside the cylinder,and then enters the clean air chamber, and finally the clean gas is discharged from the air outlet. The cartridge dust collector is operated under negative pressure. The dust-containing gas enters the tank through the air inlet.

Under the action of the negative pressure in the folding filter cartridge, the gas enters the cylinder through the filter material outside the cylinder,and then enters the clean air chamber, and finally the clean gas is discharged from the air outlet.

Our cartridge dust collector isn't just limited to improving air quality in your immediate surroundings. It is versatile and can be employed across a wide range of applications in various industries, including:

Metalworking: Our dust collector effectively filters out the tiny metal particles released during machining and fabrication processes.

Plasma/Laser Cutting: It effectively captures and filters out the airborne particles produced during the cutting process.

Grinding and Sandblasting: It traps and removes the dust produced during grinding and sandblasting operations.

Powder Coating: Our dust collector ensures a clean and dust-free environment for optimal coating application.

Shipbuilding: In the large-scale and heavy-duty environment of shipbuilding, our dust collector efficiently maintains air quality.

Tobacco and Food Processing: It helps in maintaining hygiene standards by filtering out impurities in these sensitive industries.

Electricity: It aids in preventing dust accumulation that could interfere with electrical components.

Welding and Casting: Our dust collector effectively deals with the fumes and particulates generated in these processes.

The filtration media of our dust collector can effectively filter air particles, impurities, etc., providing a cleaner and healthier work environment in various industries. Our cartridge dust collector is designed to be your trusted partner in maintaining superior air quality across diverse applications.

What is the construction of cartridge dust collector?

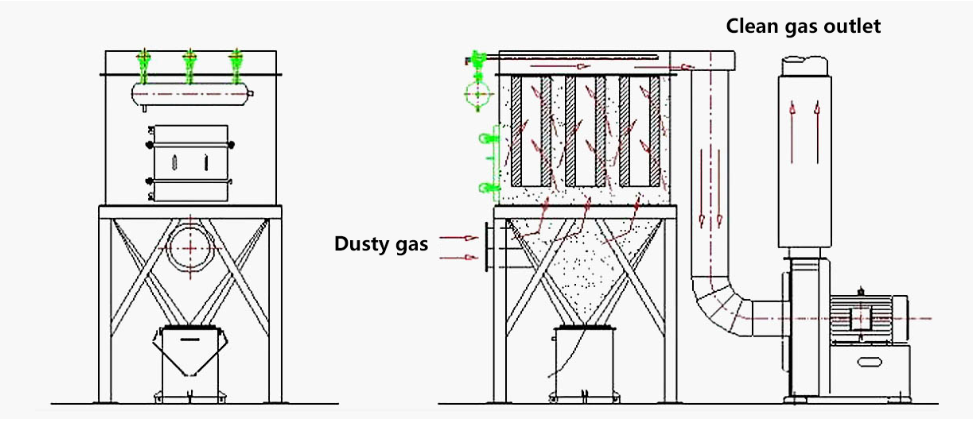

The main body is divided by a tube sheet into two parts.

The lower body is called dirty air plenum, the upper body is called clean air plenum.

The lower body includes an inlet which is connected to flexible suction pipes which carry the dirty air from the source, At the bottom is the hopper which is fitted with a rotary air lock system for continuous discharge of the dust particles.

The upper body includes the main filtration system.

It includes the rows of filter cartridge, each cartridge is attached to the tube sheet.

Above the tube sheet in the upper body is the cleaning system of the machine. It includes the rows of blowpipes, each blowpipe is drilled with holes and connected to the air reservoir which has solenoid valveattached to it.

The upper body also includes the outlet which is connected to a series of pipe, used to carry the filtered air.

What is the working principle of it?

The superior performance of our cartridge dust collector lies in its efficient and effective filtration process. Here is a detailed walk-through of how it works:

Dirty air enters the system through the inlet and passes through the filter cartridge. This is where the initial filtration process begins.

A baffle plate is used within the system. The heavier particles fall down into the hopper due to this design, while the lighter particles get deposited on the exterior surface of the filter cartridge.

The clean air, now free from heavy and light particles, passes through the cartridge and moves up to the clean plenum. The purified air is then discharged from the outlet.

As the filtration process continues, a certain level of dust gets deposited on the filter cartridge. This creates pressure, which is detected by a gauge fitted on the machine. This detection triggers the start of the cartridge cleaning process.

Air stored in a reservoir is released and carried by the blowpipes. This high-pressure air is released into the filter cartridge, one row at a time.

The airflow through the cartridge releases the deposited dust and cleans the cartridge. The dislodged dust particles then fall off into the hopper.

This cleaning process takes place at regular intervals of time, ensuring that the filtration process runs smoothly.

This efficient and self-cleaning mechanism is what makes our pulse jet dust collector stand out. It ensures that your environment maintains optimal air quality at all times, making it a reliable choice for diverse industries and applications.

Our cartridge dust collector isn't just an air filtration system—it's a comprehensive solution designed with your needs in mind.

Here's why our product stands out:

Ease of Installation and Maintenance: Our cartridge dust collector is designed for user-friendly installation and maintenance. You won't need to navigate complex assembly instructions or worry about difficult upkeep.

High Filter Efficiency: With a filter efficiency of 99.9%, our dust collector guarantees almost complete dust and impurity removal from the air. This ensures that you're always breathing cleaner, healthier air.

Pleated Media Design: The pleated media design of our dust collector significantly increases the filter area. This means more air can be filtered at any given time, enhancing the overall efficiency of the system.

Low Operating Resistance: Operating at a low resistance of 500-800pa, our dust collector helps reduce energy consumption. This not only makes it a cost-effective choice but also a greener one, helping you contribute to environmental sustainability.

In all, our cartridge dust collector is more than just a product—it's a promise of superior air quality, easy maintenance, high efficiency, and energy savings. It's an investment in better health and productivity for your workspace.