Dust collector equipment is used to improve the quality of air released from industrial and commercial processes by collecting dust and other impurities from the air or gas. It's designed to handle heavy dust loads. Here's a bit more detail about the two types of dust collector you mentioned:

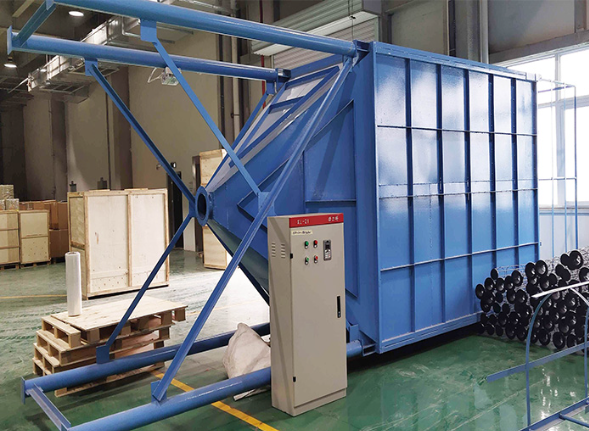

Pulse Jet Baghouse Collector: This type of dust collector uses fabric dust bags and a high-pressure jet of air to remove dust from the air. The dust-laden air enters the baghouse and is filtered through the bags, with the dust being deposited on the outside of the bags. Periodically, a burst of compressed air (the "pulse") is released into the bags, shaking loose the accumulated dust, which then falls into a hopper for disposal. The clean air is then released back into the environment. Pulse Jet Baghouse Collectors are efficient and reliable, and they can handle heavy dust loads.

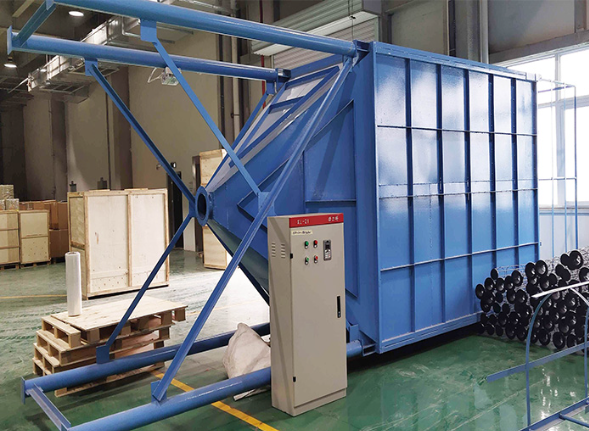

Cartridge Dust Collector: These are similar to the baghouse collectors but use cartridge filters instead of bags. These cartridge filters are often cylindrical and can be more efficient at capturing dust than traditional bag filters. They are easier to replace and often provide a larger filter area, making them a good choice for lighter dust loads or for applications where the dust is particularly challenging to filter. The dust is filtered out as the air passes through the cartridges, and the clean air is then exhausted.

Both types of dust collectors play a crucial role in maintaining air quality in industrial and commercial environments. They help to ensure the air released into the environment is clean and safe, and they protect equipment and people from harmful dust and particulates.

What is the working principle of the two types of dust collectors?

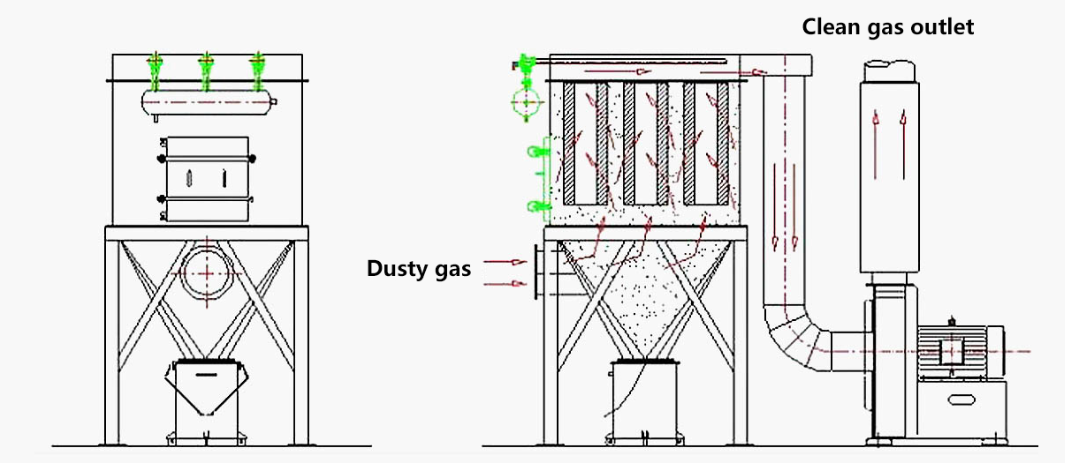

Baghouse dust collectors:The dirty air enter the system through the inlet and pass through the filter bags.

Due to the use of baffle plate, the heavy particles fall down into the hopper, the lighter particles get deposited on the exterior surface of the filter bags, only allowing the clean air pass through the filter bags up to the clean plenum. The clean air is discharged from the outlet. This is the general process take place in this system.

When a certain level of deposited dust is reached on the filter bag, a pressure is created, and it is detected by the gauge fitted on the machine. And this starts the process of cleaning of the filter bags.

Air stored in the reservoir is released which is carried by the blowpipes.

The high-pressure air is released into the filter bags one row at a time.

The air passing through the filter bags releases the deposited dust and clean the bag, the dust then fall off into the hopper. This process takes place at regular intervals of time, and this allow the filtration process runs smoothly. This is how a pulse jet dust collector works.

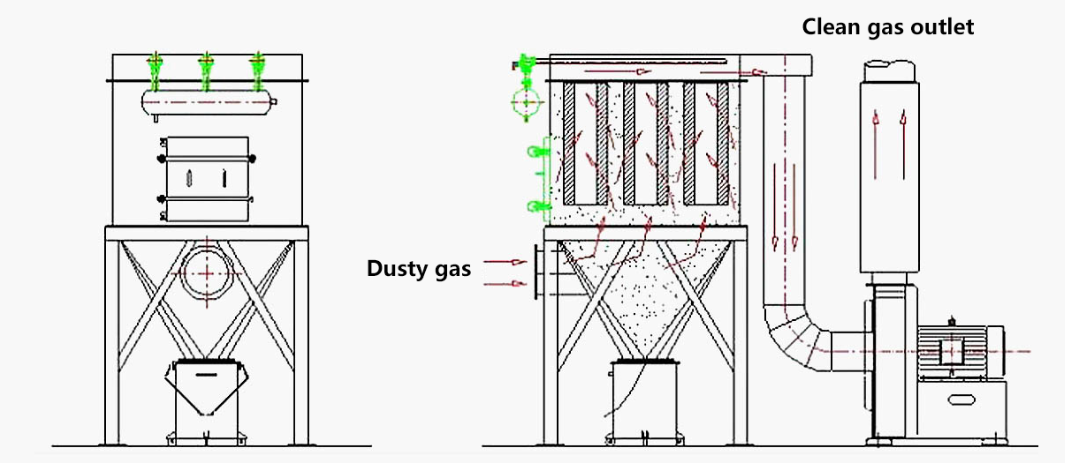

Cartridge Dust Collector

The dirty air enter the system through the inlet and pass through the filter cartridge.

Due to the use of baffle plate, the heavy particles fall down into the hopper, the lighter particles get deposited on the exterior surface of the filter cartridge, only allowing the clean air pass through the cartridge up to the clean plenum. The clean air is discharged from the outlet. This is the general process take place in this system. When a certain level of deposited dust is reached on the filter cartridge, a pressure is created, and it is detected by the gauge fitted on the machine. And this starts the process of cleaning of the filter cartridge. Air stored in the reservoir is released which is carried by the blowpipes.

The high-pressure air is released into the filter cartridge one row at a time.

The air passing through the cartridge releases the deposited dust and clean the cartridge, the dust then fall off into the hopper. This process takes place at regular intervals of time, and this allow the filtration process runs smoothly. This is how a pulse jet dust collector works.

What are the application fields of dust collector?

Dust collectors have extensive applications across diverse fields due to their ability to control and remove dust and other pollutants. Here are some of the key application fields:

Industrial Manufacturing: Dust collectors are widely used in factories and manufacturing facilities, such as metal fabrication, textiles, chemical production, and food processing. They help remove dust and particulates generated during production processes.

Woodworking and Carpentry: In woodworking shops, dust collectors are crucial for removing wood dust and chips generated from cutting, sanding, and other woodworking processes.

Pharmaceuticals & Chemicals: In pharmaceutical and chemical industries, dust collectors handle potentially hazardous dust and fumes, protecting workers and preventing cross-contamination during the manufacturing process.

Mining & Quarrying: Dust collectors are essential in the mining industry to filter and control dust produced from extraction, crushing, grinding, and other processes.

Power Generation: In coal-fired power plants, dust collectors help control and reduce the amount of fly ash and other pollutants released into the atmosphere.

Construction: On construction sites, dust collectors help manage and reduce dust levels, improving air quality and protecting workers' health.

Agriculture: Dust collectors are used in agricultural processes, such as grain handling and animal feed production, to control dust and other particulates.

Waste Management: In waste treatment facilities, dust collectors help control odors and particulates, improving the air quality for workers and the surrounding environment.

These are just a few examples. Dust collectors can be tailored to suit the needs of almost any industry or application where dust or particulates are a concern.

What are the values of dust collector in industrial system?

Dust collectors play a crucial role in industrial systems, offering several key benefits:

Improved Air Quality: They help to improve the quality of air within industrial facilities by removing dust and other airborne particles, leading to healthier work environments and reducing the risk of respiratory issues among workers.

Equipment Protection: Dust can be highly damaging to machinery and equipment. By removing this dust, dust collectors can help to prolong the lifespan of these assets, reducing maintenance costs and downtime.

Regulatory Compliance: Many industries are subject to regulations regarding air quality and environmental impact. Dust collectors can help businesses to meet these standards and avoid potential fines or sanctions.

Product Quality: In sectors such as food processing, pharmaceuticals, and electronics, dust can negatively affect product quality. Dust collectors help to ensure that these products are produced in a clean environment.

Reduced Fire Risk: Certain types of dust can be highly combustible. Dust collectors can reduce the risk of fires in industries like woodworking and metalworking.

Environmental Responsibility: By removing dust and other pollutants from exhaust gases, dust collectors help businesses to minimize their environmental impact.

In summary, dust collectors are an essential component of many industrial systems, offering a range of benefits related to health and safety, operational efficiency, regulatory compliance, product quality, and environmental protection.